one��、Background

Energy storage power station batteries have high energy density, large quantity and concentration. Once a fire occurs, it is difficult to control in the short term and can easily cause a domino effect. The difficulty of extinguishing is high and the danger factor is high, so the responsibility of crisis warning is significant.

At present, the safety monitoring of energy storage power stations is divided into battery body monitoring and external electrical equipment monitoring. For battery body monitoring, BMS (Battery Management System) is widely used. For electrical equipment outside the battery body, conventional detection systems such as residual current detection, temperature detection, and electromagnetic wave detection are often used for protection. Usually, these two systems are independent of each other and cannot comprehensively monitor and warn the overall safety of energy storage power plants.

two、solution

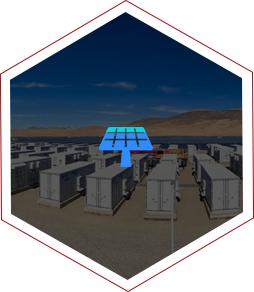

The energy storage power station online monitoring and fire warning system independently developed by Yunzhan Technology can achieve pre fabricated cabin level and battery cluster level zoning monitoring, filling the gap in existing technology and improving the reliability of the system's warning. Prefabricated cabin level adopts standard equipment, combined with nano particle detection technology and large-area active sampling, with a monitoring range covering the entire prefabricated cabin and fast response speed; The battery cluster level adopts miniaturized equipment, integrated design, and combines particle detection with characteristic gas warning to achieve battery cluster area detection.

The main advantages of the system are as follows:

1) Battery thermal runaway warning: using advanced nano particle and characteristic gas detection technology, combined with key parameters fusion analysis of the battery body, to achieve early warning of battery thermal runaway;

2) Non battery body hazard monitoring: sensitive detection of nano particles generated by overheating or discharge hazards of equipment and cables to ensure the safety of external battery equipment and operating environment;

3) Active online monitoring: adopting an active sampling method, which is faster than traditional point sensing; Real time data display, remote control, integrated analysis, compatible with other subsystems;

4) Flexible installation methods: centralized installation and distributed installation, with flexible selection based on the monitoring area.

three、case